The Plystream is a bit of a departure for Woodenwidget in many ways. Only the second non human powered transport design in the range and for once a bit impractical because of it’s shiny varnished finish. Woodenwidget has always been about simplicity, practicality and ease of build. It’s fair to say that although the Plystream is still not hard to build, it is much more involved than any of our previous designs and some might question the practicality of a varnished caravan!

All that said, one of the great things about building your own caravan is that you can finish it any way you like. In effect Woodenwidget is just showing you what is possible but you are under no obligation to follow that suggestion at all. And sometimes one has to do things that aren’t necessary practical or sensible! Perhaps the Plystream would look equally cool in a metallic silver colour so it looked like aluminium or maybe striking in a two tone effect to match a retro tow car. In any case, practical or not, I decided to varnish the Plystream and give it some bling.

When you make a decision like that it has a big effect on the design of something because you cannot hide any mistakes with varnish like you can with paint. You even have to consider how you screw it together because even tiny filled screw holes will stand out. I could have simply screwed the whole thing together and painted over the screws. That would have saved some time! It is fair to say that making a varnished Plystream and not a painted one did add to the complexity and length of time it took to build.

About that shape. Some years back the Slidavan was born. It was basically two boxes, one on top of the other and it would extend from a low box to a high one albeit with a curved fabric roof to give some character and to reduce weight. It did not need to be aerodynamic because it was so compact and tucked in behind the tow car but if a caravan was bigger and did not reduce in size it had to be aerodynamic or it would be unstable and would cost a lot more in fuel and both of these scenarios are unsatisfactory.

So then the question is: ‘How do I make it aerodynamic in shape and still make it easy to build?’ Most people opt for a tear-drop camper because they are so easy to build but they are awkward things, don’t offer any headroom and are still pretty heavy. Plus there are already so many designs out there and to me they all look pretty much the same with only slight differences. As usual it came down to thinking about the materials available to build a caravan and the trailer used to put it on.

In Europe if you can keep a trailer’s gross weight under 500 kilos it makes things very much easier, no need to register the trailer, no special insurance, and I believe you don’t even need to pay for it on the Autoroute. In any case the lighter something is the less materials it has in it, the less it costs to build. The lighter something is the easier it is to manoeuver and tow. This I learned from Lotus Guru, designer and owner, Colin Chapman. He said ‘Simplify and add lightness’ which is one of the most beautiful things I have ever heard from any designer and my mantra for many years.

The only way to keep the weight down is to use a simple one axle trailer and use that. Problem is that after two metres long they generally have twin axles which is costly and unnecessary and adds far too much weight. So straight away here was the limiting factor for a caravan. The Slidavan went easily on a two metre trailer as it was only 2.5 metres long (the length of a sheet of plywood). But I wanted to make the Plystream a bit bigger. Not much but I would be happy if it could be three metres long. That would still be small enough to easily build and move about and hopefully still weigh less than 500 kilos when stuck on a trailer.

Trouble was the biggest single axle trailer I could find was 2.35 metres long and it really needed to be at least 500 mm longer. In the end the only solution was to extend the trailer a bit which was a bit of a pain but not so hard really. The axle had to be moved rearwards a bit too to keep the trailer balanced but none of this was very difficult. So now at least I had a base long enough to build the Plystream on. The finished length would be three metres. Half a metre longer than the Slidavan which isn’t much but is nevertheless noticeably more.

How to make it aerodynamic? It’s all very well making a sleek and swooping elegant shape but how could that be easily built? Woodenwidget has always put ease of build at the top of its priorities when designing its products so whatever system was used it had to be simple enough to allow others to make it. What this basically led to to is another box but one with rounded corners. It is a compromise but it is amazing how just rounding the corners off a box can change how it looks and I think you will agree that the end result is most pleasing despite this simplicity.

Then the question becomes: ‘how does one make those corners curved?’ Most designers run a mile from curves and with good reason as curves are more complex to create than a straight line. Materials come straight. Turning straight things into curved things requires time and effort. Like the Slidavan and the Plurt before it, the Plystream would be made from 3 mm exterior plywood because it looks good, is light and when the grain is orientated a certain way can bend relatively easily. This was perfect for the rounded corners.

Bending even 3 mm thin plywood is still a bit of a challenge so normal wood glue wouldn’t cut it. Only epoxy has the gap filling properties and the strength to hold bent wood in place properly. It would be better if one could use a non toxic wood glue but it would require perfect construction techniques and that is unreasonable to ask of most builders myself included. Epoxy might be messy to use and expensive but its results are guaranteed. What you don’t want is a caravan that falls apart some years or miles down the road. Only epoxy can offer that kind of certainty and longevity.

The roof corner areas had me stumped for a while. I really did not know how I was going to make this happen in such a way that would be easily repeatable but I started the build anyway and trusted that I would come up with something. In the meantime the Plystream needed a floor and that could be stuck together with wood glue and constructed on the actual trailer. Once that was made a framework had to be constructed to glue the 3 mm plywood to.

this pic shows the three inner roof corner pieces in place but not yet glued in

But before any of that could happen a jig needed to be made to allow the making of no less than 30 corner beams which were laminated using strips of 3 mm plywood and glued with epoxy. In fact to speed things up I made two jigs and every day I made two corner beams so that after two weeks they were all made. These corner beams were attached to straight beams and the framework took shape. In the end the whole framework only weighed just 23 kilos which was very promising. At this stage it did not have very much strength but I knew that as each panel was fitted it would get stronger and stronger.

To give the structure strength all the inner curved corner pieces were bent and glued in first. The plywood has to be cut from the sheet in a certain way as plywood bends easier in one direction than an other. If you don’t get this right, there’s no way you’ll ever get the plywood to bend without breaking or stressing the framework out too much. Once they were all in place the XPS insulation was added and then the outer curved pieces were fitted. Now the structure was getting quite strong and it was time to consider how to make the inner and outer top roof corner areas.

At first I thought I would use four pieces on the inside but it soon became obvious that although it might have been possible it was not easy and that would not do. So in the end I created a kind of ‘joggled’ arrangement where I used three pieces and the centre one had a kind of arrow shaped top to it. Using just three parts simplified the process as the centre piece could be fitted and then templates made for the remaining gaps.

Obviously XPS would be too rigid for the corner section insulation so instead I used some wool that I had left over from another job but any soft material would have worked. It’s never easy making curved things from straight materials and it’s even harder when the curves go in two directions. In the end the outside roof corners had to have four pieces. It could have been ‘rounder’ if I had used six pieces say but to keep the build as simple as possible I went with the minimum which was four. The pieces have to be glued in one at a time so that the next piece has something solid to join to. It took a while to do the inside and outside corners but that was to be expected as all in all there are 28 pieces making them up and that is almost half the number of panels in the entire caravan!

Once all the curved panels were on the interior flat panels were fitted, the XPS fitted and then the outer panels went on. These had to be screwed on using temporary screws whose holes were later filled with glued in matchsticks. These were then covered conveniently by the head of a brass furniture tack which also added the effect of rivets and disguised the joins between the panels nicely. If you were painting the Plystream you wouldn’t need to do any of this but actually I rather like the rivet effect. I feel that the whole thing might look a bit too smooth and uninteresting if they were not there. But as I mentioned earlier, how you choose to finish your Plystream is up to you.

Once the panels were on the whole structure was feeling much stronger and once the interior went in it would be stronger still. It is really amazing just how strong and rigid the structure is once the whole thing has been built. What is even more amazing is how the whole thing, trailer included, only weighs 300 kilos! I had hoped for about 350 so I was very pleased indeed.

The interior is very simple, just two bunks wide enough to sleep on with seat back cushions mounted on plywood which simply drop between the bunks to make a huge double. A simple galley with hob and sink and shelf below with the opposite side left open for storage, carrying of large items or maybe a shower. Again, the builder can choose to fit their Plystream out anyway they like.

Thanks to its simple and symmetrical shape the Plystream can be scaled up or down (to a point) in all dimensions to suit the builder’s needs or to fit an existing trailer.

On the road the Plystream behaves very well, thanks to its light weight you don’t really notice it and when trucks zoom past it’s unaffected. Although not massively aerodynamic those rounded corners clearly help massively. Towing caravans has always seemed to me a rather ridiculous thing to do. They always seem so big and cumbersome and there is always a long queue of impatient cars following in its slow wake. Yet hitch up a caravan lighter than most trailers and it’s a different experience altogether.

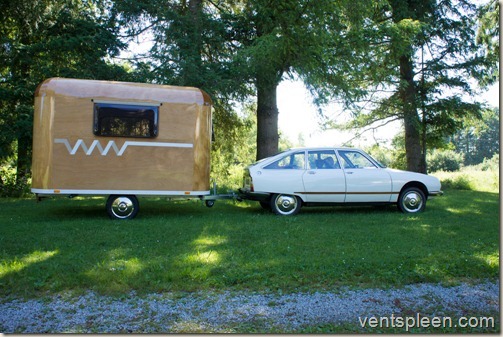

Everyone seems to love the Plystream with its retro looks and shiny finish. Everywhere you go people wave and smile. It feels good to tow an interesting caravan and not some modern generic plastic eyesore. Buying all new materials it cost just 3000€ to build which is a fraction of the price of even the cheapest caravans on the market. It will take about 350 hours to build a Plystream, maybe less if you are not mad enough to varnish it! You don’t need a huge amount of space to build one either as it is all built on to the trailer but you will need a doorway high enough to get it out once it’s made!

Camping in the Plystream is a pleasure. As it is fully insulated and even has double glazed windows it’s a very cosy place to be even if it’s raining or cold outside. It’s nice to be able to stand up in a space even with the double bed in place. The best thing about the Plystream is how easily you make friends with it. Everywhere you go people want to know all about it. That never happens with your white plastic modern caravan!

This Plystream is towed by a 1979 Citroen GS Pallas, a very cool car and it goes beautifully with the Plystream as they are both aerodynamic and funky as. The Plystream would also look very cool towed by a split screen VW van in matching retro colours or maybe it could even serve as a very cool food truck at festivals. I’m looking forward to seeing how future builders finish their Plystreams and how they use them.

I dedicate this design to Colin Chapman. He has inspired my designs for decades but until now I have never given him the credit he deserves for this inspiration. Thank you Colin. You were a legend and your genius lives on in the strangest places.